Many FMs are often seeking benchmarking data to measure how they organization is performing. When asked about what they want to learn they will often reply that what they would like to see is a table or chart showing their performance compared to others.

Well, not all charts provide a realistic picture of your benchmarked costs. Comparing data or even processes isn’t a very effective way to improve your performance unless the comparisons are made with a relevant peer group. Let’s take a manufacturing facility located in Florida and compare their custodial costs with some different peer groups to see how they are doing.

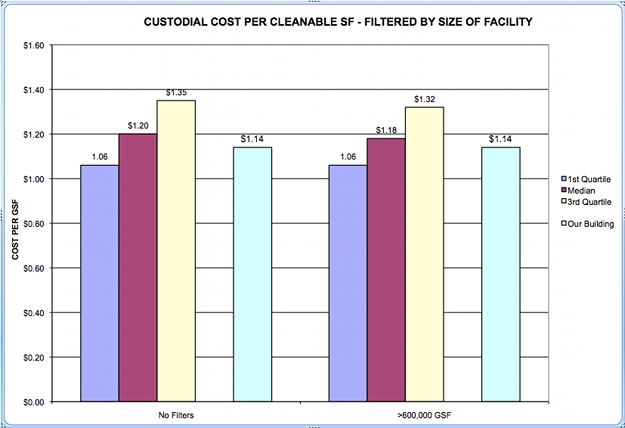

We’ll use cleanable area as the key performance indicator (KPI) since this normalizes the cost of janitorial services against the actual area cleaned. In Figure 1 below, our custodial costs are $1.14 per cleanable square foot. We have shown the 1st Quartile, Median and 3rd Quartile points for reference. Without applying any filters our building’s custodial costs are in the second quartile — near the middle of the 2nd quartile range.

If we filter this sample for size of the facility our relative performance stays about the same; we are still near the near the middle of the 2nd quartile range (note that the 2nd quartile cost is nearly the same both without and with the filter ($1,18 and $1.20, respectively). Clearly the size of the facility, at least in the 600,000 GSF area and above, is not a critical factor in comparing benchmarked custodial costs. We will need to look at some other filters to see if there is a better peer group.

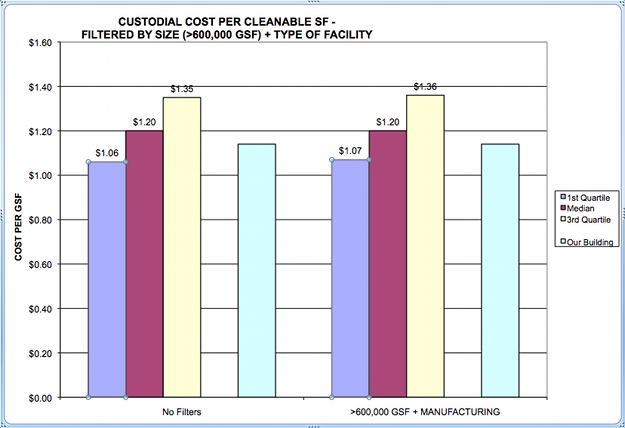

Let’s take a look at the type of facility and see if this has a significant impact on our benchmarked costs. In Figure 2 below, the cost of our custodial is still $1.14 per gross square foot (GSF); it won’t change no matter what peer group we compare ourselves to. Again, we have shown the 1st Quartile, Median and 3rd Quartile points for reference. Our building’s custodial costs are closer to the 1st quartile based on this filter set since the 1st quartile costs are slightly higher. This is a bit closer to being the right peer group: manufacturing facilities that are greater than 600,000 GSF; but perhaps, there is a different filter that will do even better.

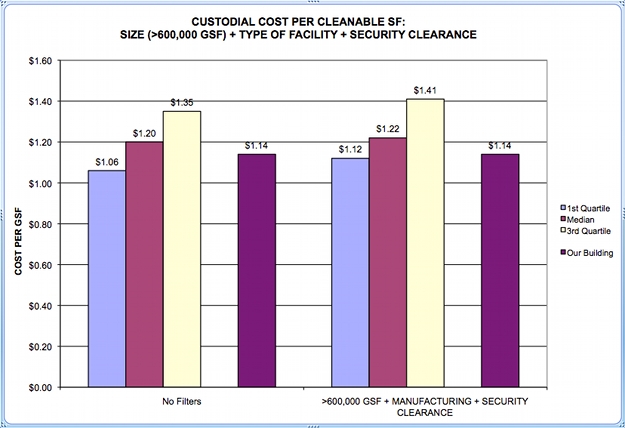

Let’s see if the security clearance requirements will have a more significant effect on our custodial costs. Since this is a manufacturing facility that requires a security background check for all employees and contractors entering the facility we will compare our costs only with those sites requiring the same level of clearance. In Figure 3 below, we compare our costs to our peer group: >600,000 GSF, Manufacturing, and Security Clearance = Yes. This really changes our reference points our first quartile peer group costs are about 8 percent higher with and our relative performance has moved to almost the first quartile. Security clearance requirements for the workforce clearly has a significant impact on our custodial cost performance.

What is really happening here is that the FM is realizing that looking at facilities without good peer group comparisons is a real waste of time. You need tools to iterate your way to the appropriate peer group for your specific situations. General numbers may be a good starting point but to really make informed decisions a more detailed breakdown by criteria that affect operating costs is necessary. That is the only way one can compare the benchmarked facility to one that is best-in-class.

We define that “breakdown” as using a set of filters. Each of the below items becomes a filter:

- Industry type

- Age of the facility

- Climate type

- Security clearance

- Hours of operation

- Days of operation

- Union or non-union labor

- Number of employees

- Facility condition index

In actuality, there are nearly 40-50 potentially useful filters for looking at custodial metrics, and more that are germane to other operating costs, such as custodial, janitorial, and security.

Benchmarking of operating costs is popular among FMs, as these are what the FM can both measure and control. More than 95 percent of operational expenses are incurred by:

- Utilities

- Custodial

- Janitorial

- Security

Many FMs don’t go any further with the benchmarking process but nothing we’ve done so far will help improve your performance. All we’ve done is find out how we’re doing compared to our peer group (filter set). In next month’s article we will show you how these filter sets can be used to identify the best practices you could implement to improve your performance over time.