Provided by Armstrong Fluid Technology

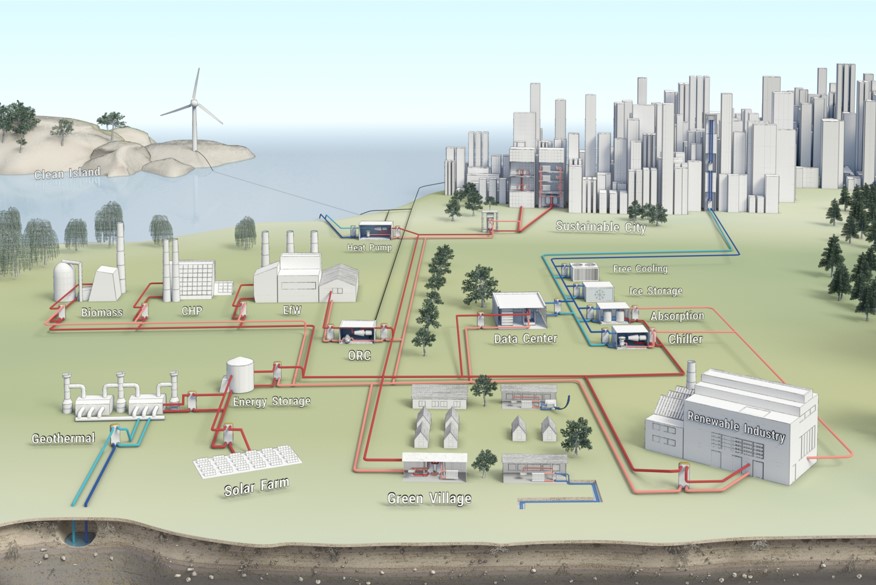

If your facility isn’t currently part of a District Energy (DE) network, chances are that it may be in the future. Driven by demand for low-cost energy and the growing number of organizations committing to net-zero targets, the global market for District Heating and Cooling Systems is expected to expand to over $754 billion by 2032.

As a single source of heating and/or cooling multiple buildings, district energy installations worldwide typically reduce primary energy demand in heating and cooling systems by 50% and can achieve operating efficiencies of up to 90%, according to the United Nations Environment Program (UNEP).

Regardless of whether the buildings you manage are in the commercial, educational, healthcare, government or transportation sectors, district energy heating and/or cooling systems provide such significant energy and cost-savings benefits that the results are impossible to ignore.

Commercial district cooling systems

A variety of case studies document the tremendous benefits of district energy systems. For example, the world’s largest interconnected district cooling system serves 45 million square feet of space in more than 100 buildings in downtown Chicago. Using thermal energy storage from Lake Michigan water, the system reduced its peak electric demand by 30MW, resulting in significant energy cost savings and energy savings for all participating buildings.

Healthcare networks

One of the largest healthcare networks in Canada is comprised of four major hospitals and a learning institute that each require considerable amounts of energy to provide reliable, 24/7 cooling to maintain critical temperature ranges. The buildings are all interconnected with an innovative district energy system that has achieved annual energy savings of 20% to 30%!

Campus district energy

Stanford University in California replaced its natural gas-fired co-generation plant with an innovative district energy system in its 8,180-acre campus through recovery of waste heat from the chilled water system. 93% of the of the campus heating and hot water needs are met by recovering chilled water waste heat.

Municipal ECO districts

Rambervillers, a community in northeastern France with a population of 20,000, captures steam from a nearby waste-to-energy plant and converts it into hot water for homes and businesses. Using an innovative Intelligent Fluid Management System (iFMS) that integrates pumps and controls with a Design Envelope Integrated Pumping System, the municipality reduced pump energy use by 30% compared to standard pump-sequencing systems.

Located nearby, the French municipality of Sarrebourg reduced the territory’s dependence on fossil fuels by creating a hot-water district heating system using wood heating to provide heat and domestic hot water to nearly 3,000 residential and commercial buildings. Using a 5MW biomass boiler as the heat source, the new system will avoid the emission of more than 123,000 tons of GHGs over the next 20 years.

Airports need for district energy

As a major consumer of energy, airports are constantly seeking solutions for significant energy savings and carbon footprint reductions. The CPK airport near Warsaw, Poland found an innovative solution with an Ambient Loop 5th generation “energy system” that features a central water loop connected to each building and the central energy production hubs. The energy that is expelled during heating or cooling in any of the buildings is reclaimed and repurposed throughout the network.

One of the major benefits of district energy systems is the scalability that supports adding new buildings and heating plants, while maintaining or enhancing energy efficiencies and cost savings. Such was the case at the Edmonton International Airport where a co-generation district energy system was expanded to accommodate a new retail complex for retail, entertainment and offices.

HVACR fluid flow system is the heart of any DE network

There are many examples showing how district energy systems around the world are generating tremendous energy and costs savings while significantly reducing carbon footprints. If your facilities are part of a DE system, you are already familiar with these benefits.

There are many examples showing how district energy systems around the world are generating tremendous energy and costs savings while significantly reducing carbon footprints. If your facilities are part of a DE system, you are already familiar with these benefits.

However, most facility managers are not aware that the “heart” of any district energy network is a technologically advanced fluid flow system that facilitates and regulates the flow of energy from a central energy source. Modern variable speed controllers integrate with building management systems (BMS) to provide best-efficiency modulation and staging of pumps, while serving as many as 16 zones.

In fact, an Intelligent Fluid Management System (iFMS) that integrates pumps and controls with a design envelope Integrated pumping system can reduce pump energy use by 30% or more, compared to standard pump-sequencing systems. Together, they can also save 30% or more over parallel pumping configurations and deliver energy savings of more than 70% compared to a constant speed system.

These intelligent fluid management systems integrate superior pump and control technology in a single packaged solution that can be designed and fabricated to customer specifications. The system is delivered factory tested and just needs to be connected onsite for a true plug-and-play solution.

You don’t need a district energy system to benefit from these solutions

Whether you are currently part of a district energy network or just need to upgrade your heating, ventilation, air-conditioning and refrigeration (HVACR) system, the innovative solutions mentioned throughout this article apply to existing installations. Intelligent fluid management systems are used in many retrofit applications to generate significant energy and cost savings.

IFMS systems are ideally suited for commercial or industrial closed-loop systems, including HVAC chilled-water systems, cooling tower installations or process water loops.

To determine if iFMS is right for your installation, get your “District Energy Guidelines” at Armstrong.