by Lon Edelman, CAFS — When installing a new HVAC system, retrofitting an existing system, or simply changing out filters as part of a maintenance schedule, facility engineers are often faced with a decision: what type of filters to install. When that decision is based on the purchase price of the filters only, facility engineers may find that the cost-in-use from an indoor air quality (IAQ) and energy consumption standpoint may not be worth it. Even within the category of pleated filters, there are some differences that can impact both your budget and energy consumption.

Pleated filters using traditional wire-backing support have been around since the 1980s. The wire backing in these filters helps the media to maintain its pleat shape and provides for more durability. Because the media in wire-backed pleated filters need not be as stiff as the media in self-supported pleated filters, wire-backed pleated filters typically allow for good airflow while still maintaining the required particle capture to meet IAQ needs. Some wire-backed filtration media is thermally bonded, using no binders or adhesives that can inhibit airflow.

Wire-backed pleated filters are typically offered in MERV 6 through 11 performance levels, although recent advances in wire-backed media technology have allowed for offerings up to MERV 13.

Self-supported pleat filters were developed in the late 1990s to replace wire-supported HVAC pleat filters in the North American market. Today, they are available from a limited number of national manufacturers at MERV 6, 7 and sometimes 8 performance levels. Manufacturers of these filters have invested in automated equipment that allows them to produce filters with very stiff media that requires no wire backing for support and little in the way of framing. These investments have allowed the manufacturers to both reduce their labor costs and use their lower cost position to sell their filters as commodities based almost exclusively on price.

Some self-supported pleated filters, however, may have some drawbacks in use. For example, in order to make the filter media stiff enough to be pleated without wire support, manufacturers may need to produce a structure that compromises air permeability. The result is a filter that can be more restrictive to airflow, and this restriction causes the HVAC system to work harder to push air through the filter, thus increasing energy costs.

Pay Attention to Cost-in-Use

HVAC system air filters perform an important function in commercial, industrial and institutional buildings. They remove dust and particles from the breathing air, thus playing a key role in indoor air quality. At the same time, they have an impact on the HVAC system’s energy consumption, the extent of which can vary depending on the amount of airflow resistance they create.

Even with the tremendous technological strides the air filtration industry has made, and with the myriad of filter media and finished filter types available, some purchasers continue to focus almost solely on the initial purchase price when specifying air filtration, mistakenly thinking that price is the only selling feature for air filters.

One of the problems with considering only the purchase price of pleated filters is that the filter’s price only encompasses the initial cash outlay for acquiring the filter. In fact, the purchase “price” is only one small component of the filter’s actual “cost.”

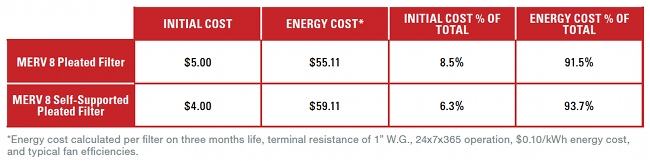

Studies have shown that the initial investment (purchase price) and maintenance count for about 18 percent of the cost to operate a filter. Energy costs associated with the filter in-use account for about 81 percent of the annual cost. The numbers in the table below show an example of the breakdown for a typical self-supported pleated filter and a supported pleated filter.

The higher energy cost of the self-supported pleated filter is related to the resistance of the air passing through the filter. The lower the filter’s resistance to airflow, the lower the energy consumption will be.

Self-supported pleated filters may have a higher resistance to airflow than supported pleated filters because they often use more binders and glues to impart stiffness to the media. Those binders and glues can clog the “pores” of the filter, cutting down on airflow, which makes the HVAC system fan work harder. On the other hand, for supported pleated filters, there are options for filter media that do not contain binders and glues, thus ensuring low airflow resistance and lower HVAC system energy costs because the fan does not need to work as hard to push the required air through the system.

Self-supported pleated filters and supported pleated filters also tend to have different dust holding capacities, which means the filter is not able to hold as high a particulate mass before reaching terminal airflow resistance. This can result in a higher filter change-out frequency, which increases the filter maintenance costs.

Sometimes, the dust holding capacity is so poor that filters can very quickly become clogged with dust, causing the force of the air handler to blow the filter right out of its housing and into the fan. Some self-supported pleated filter makers have responded to this by adding additional framing, but this step does not necessarily resolve the airflow resistance and dust-holding capacity issues.

Indoor Air Quality (IAQ) Issues

Filter purchasers would be wise to investigate the fine particle removal efficiencies of self-supported pleated filters before buying as well. Remember that there is more to a filter’s filtration efficiency than just its MERV. That is why it is important to review the efficiency values that are included in the ASHRAE 52.2 test report.

When evaluating self-supported pleated filters, pay special attention to the efficiency of the filter over all three particle size ranges: E1 (very fine particles in the 0.3 to 1.0 micrometer range), E2 (fine particles in the 1.0 to 3.0 micrometer range) and E3 (coarse particles in the 3.0 to 10.0 micrometer range.) Testing has shown that self-supported pleated filters tend to have lower E1 and E2 efficiencies than supported pleated filters.

Most of the respirable dust and particles people breathe into their lungs is three micrometers or smaller, high E1 and E2 efficiencies are critical to providing good IAQ and helping building occupants avoid illness: 50 percent of all illnesses are thought to be either caused by or aggravated by poor IAQ.

Sustainability Issues

Facilities looking to improve their environmental sustainability performance by reducing the amount of waste sent to landfills should also consider the amount of filter media that goes into both supported and self-supported pleated filters — filter media that will be sent to a landfill upon disposal.

In most cases, self-supported pleated filters use more and heavier media, which is needed to help impart stiffness and durability. However, supported pleated filters of the same filtration efficiency tend to contain less media, for less of an environmental impact upon disposal.

The longer filter life of a supported pleated filter (which doesn’t need to be changed as often thanks to a longer time until terminal airflow resistance than self-supported pleated filters) also translates into fewer filters being disposed of during a particular timeframe.

Don’t Be Swayed By Price, Focus on Cost

Even as the national economy moves toward recovery, many businesses continue to cut corners when it comes to spending on consumables. While saving money is a good idea in theory, air filter purchasers should be more practical and look beyond the initial purchase price to the filter’s total cost in use.

Next time you are in the market for air filters, if you are considering both self-supported pleated filters and supported pleated filters, be sure to evaluate the energy efficiency of the filter vis–vis its airflow resistance to find out if you are really saving money or will end up spending more.

Lon Edelman, CAFS is the market manager for Kimberly-Clark Filtration. Kimberly-Clark offers a free online filter cost calculator to help you make an informed decision. Visit www.kcfiltration.com for more details.