High-pressure boilers produce steam to generate power. Steam produced by high-pressure boilers passes through turbines, generating mechanical energy, which is then converted to electrical energy for use in various process equipment.

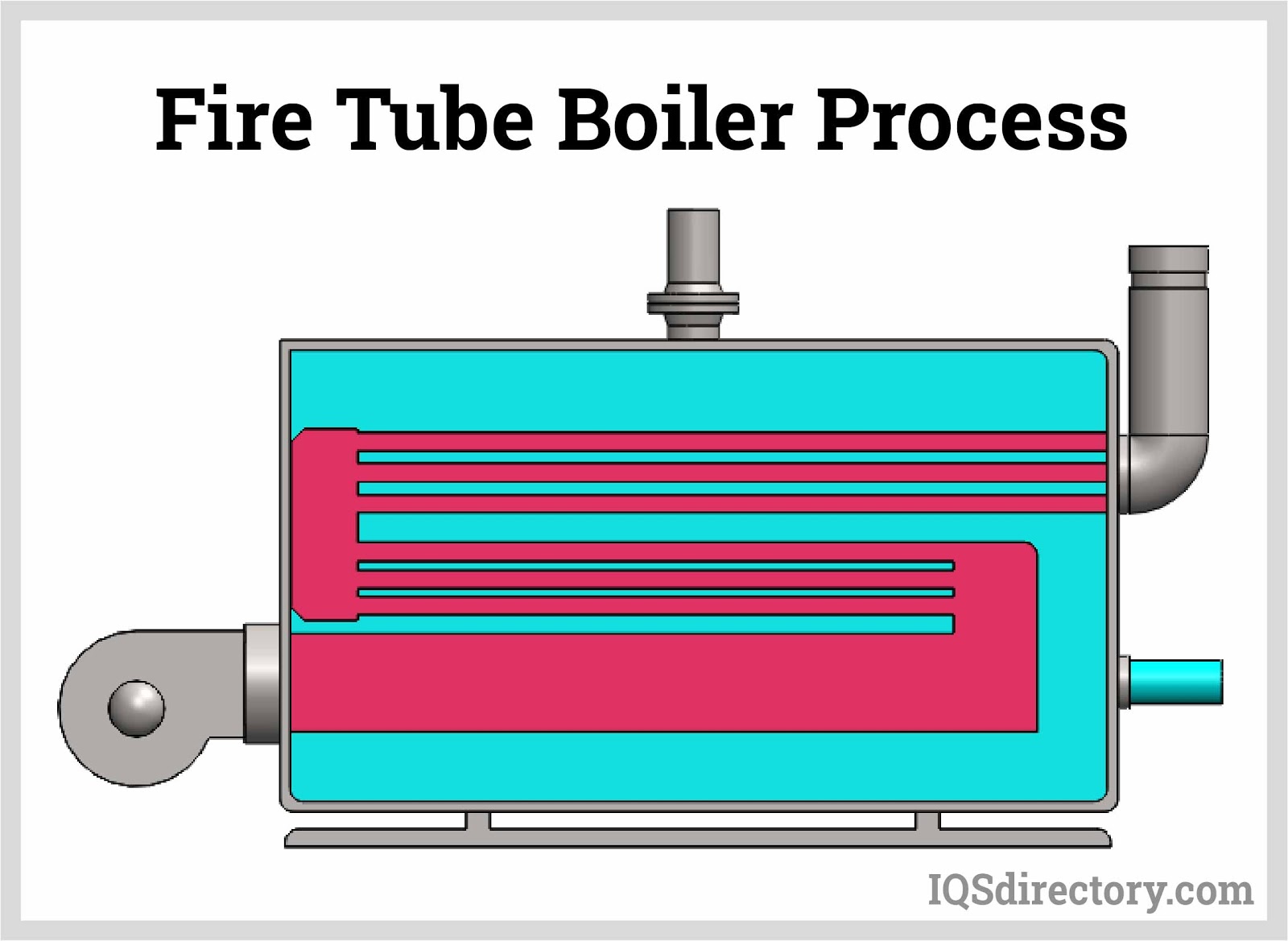

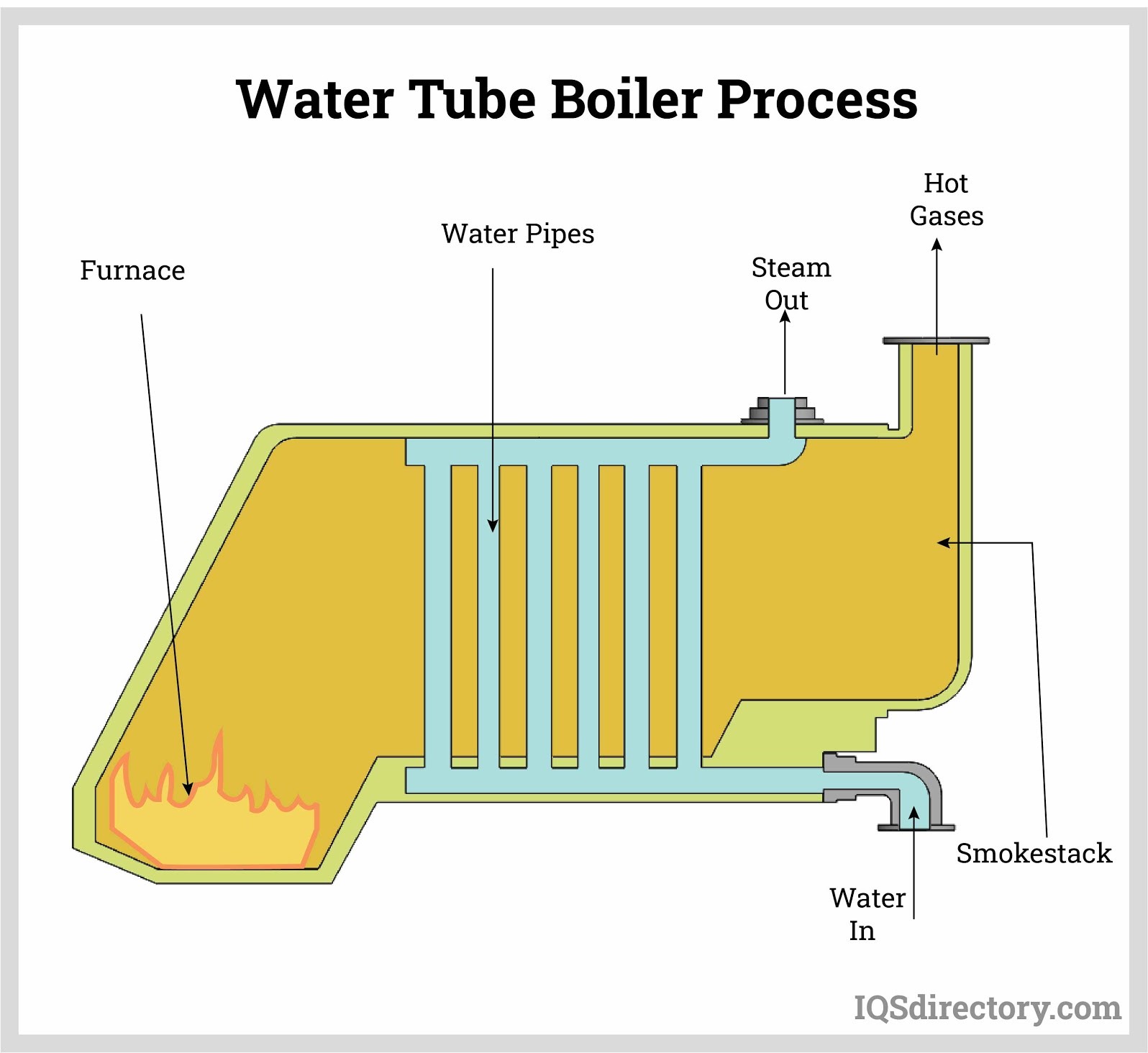

Hot gases from burning fuel such as coal, oil, and gas transfer their heat to feed water to produce steam. Water tube boilers and fire tube boilers are the two forms of the boiler. Water tube boilers produce steam by heating the water inside the tubes, whereas fire tube boilers produce steam by firing hot gases through the tube immersed in water.

Basic Parts of a Boiler

A high-pressure boiler has an operating pressure of 80 MPa and above. Otherwise, it is a low-pressure boiler. High-pressure boilers are the preferred option for power generation over other methods because of their cost-effectiveness. Water is an inexpensive raw material that can carry large amounts of heat when turned into steam. Most high-pressure boilers have 95% thermal efficiency. Different high-pressure boilers include La Mont, Benson, Loeffler, Velox, Cornish, and Babcock and Wilcox boilers. Modern designs of high-pressure boilers with a varying number of tubes, geometric orientation, fuel source, pressure, and water and gas circulation mechanisms are widely available, but the basic parts of a boiler are as follows:

-

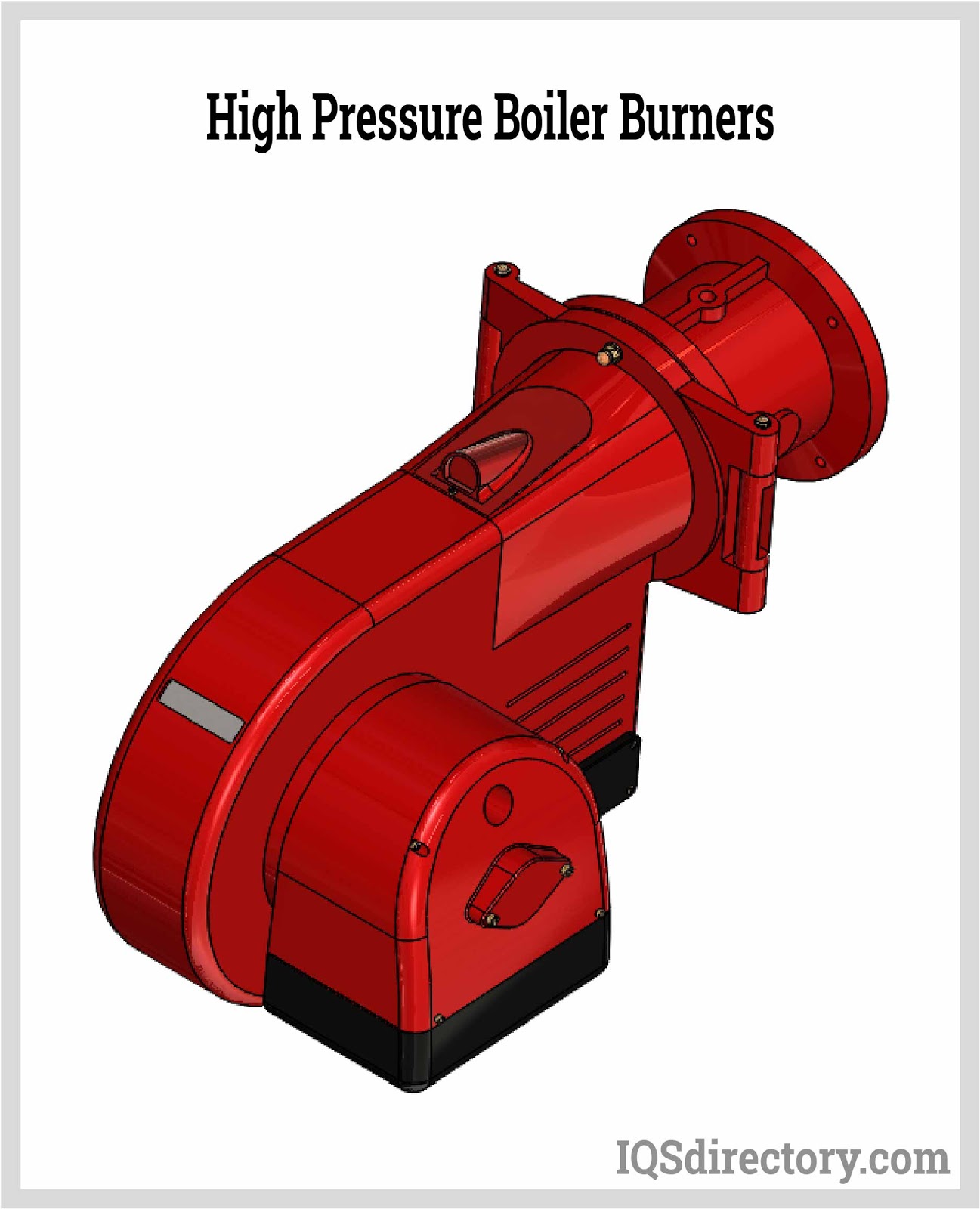

Burner. It ignites the fuel after it activates a thermostat.

- Combustion Chamber. It is a box made of cast iron or steel, where the fuel is burned.

- Grate. It is a platform with spaced bars located inside the combustion chamber. It is where solid fuels such as wood, coal, or biomass are placed for efficient burning.

- Heat Exchanger. It transfers the heat of hot gases from the combustion chamber to the water without direct contact.

- Steam Drum. It separates the steam from water with the steam leaving at the top and the water being drawn at the bottom.

- Economizer. It is where the feed water enters the boiler and is preheated by the flue gas. It is an energy-saving feature, maximizing the use of the heat of existing hot gases.

- Superheater. It further heats the steam leaving the steam drum to evaporate the remaining water, which is harmful to downstream equipment.

- Feed Pump. It pumps the water to the boiler.

- Air Preheater. It heats the air supplied to the boiler using the recovered flue gas to increase thermal efficiency.

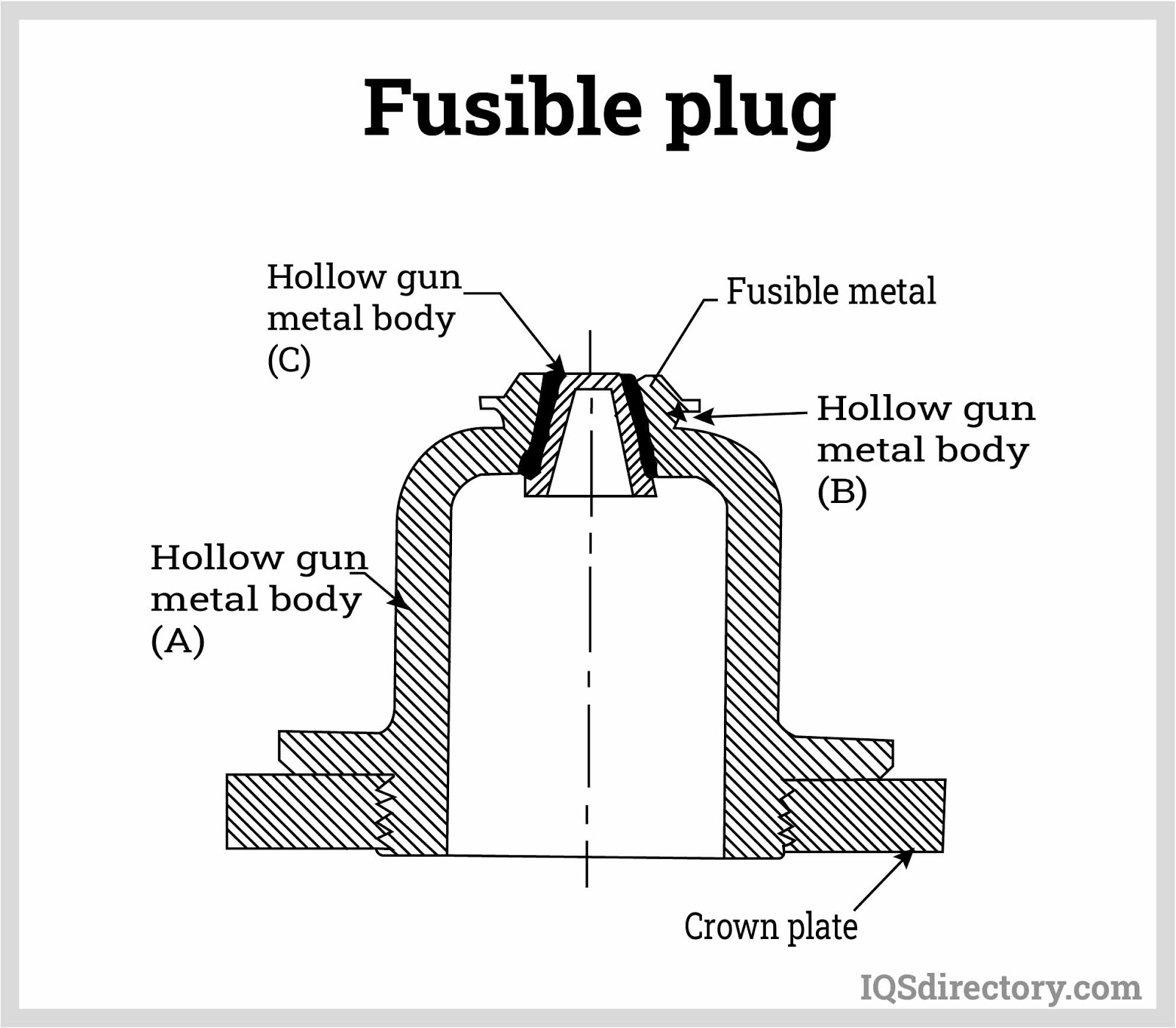

- Safety and Control Devices. It is a group of devices that keep the safe and continuous operation of boilers. It includes a boiler controller, water level indicator, pressure gauge, safety valve, stop valve, fusible plug, blow-off cock, and feed check valve.

Hazards and Safety Precautions of Boiler Operation

High-pressure boilers contain hazards that can lead to serious and damaging incidents such as explosions. Meltdown due to low water supply, thermal shock because of contact of cold water to an overheated surface, and combustion of leaking liquid fuels are some instances when not given immediate attention would result in an explosion. These events could be prevented by implementing safety measures such as having a boiler log, frequent checking of water levels and pumps, and installing steam traps and safety valves.

The Occupational Safety and Health Standards Act (OSHA), National Fire Protection Association (NFPA), and American Society of Mechanical Engineers (ASME) outline the guidelines for the proper and safe handling of high-pressure boilers in different situations.

To learn more about the standards and regulations for the proper and safe handling of high-pressure boilers, visit the following: OSHA Standard 1926, NFPA 85, and ASME Boiler and Pressure Vessel Code.

For additional information about high-pressure boilers and boiler safety as well as links to leading high-pressure boiler manufacturers and suppliers, visit the IQS Directory website.

This article was submitted to FMLink by IQS Directory. Created by Industrial Quick Search (IQS), IQS Directory is a comprehensive listing of manufacturers and suppliers serving major segments of the OEM industrial manufacturing marketplace across the United States and Canada. The website provides articles and resources on all types of industrial equipment.