Countdown for Meters

Regulations for energy metering in new and existing buildings are often not clearly understood. Mike Lawrence explains the requirements and offers some solutions.

Requirements for energy metering are confusing and as a result many people have failed to meet mandatory requirements while others have adopted unnecessarily complex and costly solutions. Sometimes it is possible to install a relatively simple, cost-effective metering system that is future-proofed to allow for more advanced automatic metering and trending (AM&T) systems to be introduced at a later stage.

The main driver behind the latest requirements is the Energy Performance in Buildings Directive (EPBD) which came into force in January 2003. This is intended to promote improved energy performance in buildings through cost-effective measures. It has four principal elements:

- To establish a calculation methodology so that energy performance of buildings can be calculated, taking account of all the relevant factors affecting energy use.

- To establish minimum energy performance requirements through regulations covering new buildings and refurbishment of large existing buildings.

- To introduce Energy Performance Certificates (EPC) whenever a building is built, sold or rented.

- To introduce regulations requiring inspection of boilers, heating systems and air conditioning systems.

|

|

| A Smartboard with one (left) and both covers removed |

The EPBD also introduced the UK Building Regulations, Part L2:Conservation of Fuel and Power in Buildings other than Dwellings which introduced new requirements for submetering aimed at encouraging an effective sub-metering strategy. Regular inspection of airconditioning systems also became applicable to systems over 250kW from January 4th 2009and will apply to all air-conditioning systems over 12kW by January 4th 2011.

Landlords

Metering requirements for landlords is a separate issue relating to the type of meter required where billing of tenants carries legal implications. The Measuring Instruments Directive (MID) which became effective from October 2006, introduced a Europe-wide standard for such meters. In the United Kingdom, it replaced OFGEM approval, although meters approved by OFGEM before November 2006 can still be manufactured and verified until 2016. Only meters used in legal transactions need to be MID certified. MIDcompliant instruments will provide similar standards of accuracy at lower cost. Building Regulations Part L2 applies to nondomestic premises with a floor area greater than 500 sq m (including separate buildings on multi-building sites.) It calls for the installation of energy sub-metering so that 90 per cent of the estimated annual consumption of each fuel can be assigned to different end-use categories such as lighting, heating, ventilation, pumps and fans. These requirements apply to electricity, gas, LPG or oil.

These requirements occupy a very small section of Part L2 but the document refers to CIBSE Technical Memorandum TM39:Metering Energy Use in Non-domestic Buildings as a source of detailed guidance on how to meet the sub-metering requirements. TM39 is an updated version of an earlier document, CIBSE General Information Leaflet 65 (GIL65) Metering energy use in new non-domestic buildings, which can be downloaded free of charge from www.cibse.org/pdfs/GIL065.pdf. There are two sub-clauses to the L2 requirements. These call for:-

- Separate monitoring of the performance of any low and zero carbon (LZC) system

- Provision of automatic meter reading and data collection facilities in any building having a total useful floor area greater than 1000 sq m.

|

|

GIL65 gives specific recommendations for plant and equipment for which separate metering should be provided as for motor control centres feeding pumps and fan loads greater than 10kW; boiler installations greater than 50kW; chiller installations greater than 20kW, electric humidifiers greater than 10kW and final electricity distribution boards greater than 50kW. The majority of final distribution boards, particularly Type B (three-phase) designs, are greater than 50kW and should therefore have provision for metering. There are various approaches to submetering. In some cases all metering is provided at the main switchboard. This has the advantage that meters are all in the same location so manual collection of data is easy.

However, each metered load will need to have its own feeder from the switchboard. On some sites, MCCB panelboards (normally equipped with moulded-case circuit-breakers for protection of the board and outgoing circuits) provide sub-distribution to final distribution boards and to loads such as lifts, ventilation or air-conditioning plant. This will require sub-metering at the panelboard. Bolton metering chambers and associated meter packs are available for panelboards. Lighting poses a special challenge. It can represent one of the principal loads requiring metering but tends to be a distributed load, normally fed from final distribution boards which also supply small power circuits. If metering is to be provided at the main switchboard, it will require separate feeders and distribution boards to distinguish between lighting and non-lighting loads. The solution is to provide separate metering of grouped lighting and power circuits at the final distribution board. This can be achieved with custom-built boards incorporating metering (an expensive option), meter packs (installed alongside, or below, standard distribution boards) and distribution boards with integral metering.

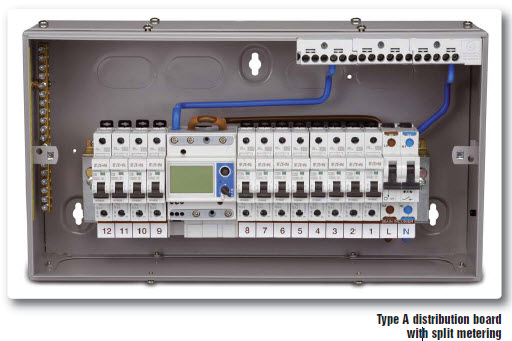

These options are available with both Type A (single-phase) and Type B (three-phase) boards and include both single-channel metering of the entire distribution board or split metering of grouped lighting and power circuits.

Remote reading

The basic function of electricity meters is to measure energy use (in kWh) but many can indicate other parameters such as line voltage and current, reactive power (kVAr), power factor and peak demand, all of which contribute to a knowledge of a building’s energy performance. Ideally meters should include remote reading capabilities even if these are not put to immediate use. As a minimum this should be a pulsed output offering remote measurement of kWh. A better solution is a Modbus design that provides information via an RS485 connection. With Modbus RS485 connection, information can be read directly from the meter, and if connected to energy management system (EMS/BMS), it can provide a more informative energy monitoring capability.

Type A (single-phase) final distribution boards are available with integral meters. Eaton offers a 12-way unit with a singlechannel meter or 8+4 way and 6+6 way split metered boards with integral two-channel meters. The division of power and lighting circuits in the 8+4 way board can be 8/4 or 4/8. The two-channel meter provides true net values for both groups of circuits and is offered in pulsed output or Modbus versions. Separate meter packs are also available for installation with standard Type A and Type B final distribution boards. For Type B applications there is a 100A direct connection unit with OFGEM-approved meter and a MID certified meter option for billing purposes; a 200A unit complete with current transformers and a choice of meter types; and a 125/160A split-load meter pack for installation below two standard Type B distribution boards. This latter unit incorporates a 125A or 160A disconnect switch incomer, two multifunction meters and two sets of current transformers. This means that a single feeder can supply both boards via the disconnect switch. Pre-wired cable looms simplify the installer’s task.

Split power

The latest development from Eaton is a range of 200A Smart Split Power and Lighting Distribution Boards with an integral meter capable of providing net readings for grouped lighting and power circuits and a total reading for the board. The boards are suitable for threephase or single-phase applications. A unique feature of the units is the use of a smart summing meter and a high-integrity shrouded busbar with embedded transducers. The embedded transducers result in a compact design and facilitate the use of a single highintegrity busbar, thereby avoiding use of a split busbar with cable interconnection. Specifiers and installers do not need to go to the expense of custom-built distribution boards and panelboards to ensure compliance with Building Regulations Part L2. A range of metering solutions is now available for Type A and Type B boards including add-on meter packs for use with standard distribution boards and distribution boards with integral metering capabilities. The design of these units minimises the amount of on-site work for the contractor and the standardised design allows boards to be sourced through the normal electrical wholesaler network.

Where greater sophistication is required, Ethernet connectivity can be used to integrate the sub-metering into a comprehensive energy management architecture for effective monitoring, control and management of the complete energy infrastructure in large sites.

Mike Lawrence is Product Line Team Leader — Commercial Assemblies, at Eaton